During the year and a half my streamliner was in Vancouver, Canada, I wasn't idle.

I knew there would come a day when Black Lightning would be back in my control, so I started to prep for that day.

I continued to buy back the machine shop tools which I'd lost in the court battle.

Welder, mill, lathe, grinders, buffers, sanders, bead blaster, and so on, began to be acquired.

Eventually I managed to put together a pretty good workshop and home for Black Lightning's return.

Let me tell you it was one of the greatest feelings I've had in a long time when I pulled into my drive that day and commenced to off load the streamliner.

My dream of setting the LSR with Black Lightning had not diminished during her absence.

In fact her absence had only rekindled the desire in that dream.

Like a long lost lover, I first looked her over, seeing that she was a bit worse for the experience, but she was still mine, and she was home at last.

I spent the next three weeks contemplating my next step.

What kind of streamliner did I want to take back to the salt?

I'd heard of a fellow by the name of Mike Akatiff, who was building the "Ack Attack", a twin engine turbo powered Hayabusa streamliner.

Denis Manning was in the process of getting his multi million dollar "Lucky 7" going, and during 2002, Sam Wheeler topped 300 mph with his Kawasaki, EZ Hook.

I knew what I had built wouldn't be a competitive motorcycle against these three streamliners.

Originally I had built the Vincent streamliner to challenge the 322+ mph record from the twin engine Harley streamliner, Easy Rider, piloted by Dave Campos.

It seemed like all of the sudden anybody and everybody with the where with all was going for the LSR for motorcycles.

In order to compete in this arena, I would have to build a more competitive Black Lightning.

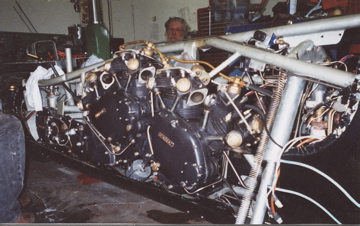

The 2000cc Vincent power plant would be increased to 3000cc, using Terry Prince 4 1/2" stroker crankshafts.

The main shafts would be increased to 1 1/2" and the rear crankshaft main shaft would be made one piece for driving the blower.

These shafts finally came about courtesy of John MacDougall.

Overbore cylinders would be stuffed into special cylinder muffs made by Terry Prince.

Again, the machine work for the muffs was accomplished by John MacDougall.

I had decided that the 5 speed Surtees transmission wasn't up to the task of the larger machines.

I knew the Easy Rider machine had used a Muncie three speed "rock crusher".

The transmission had been hand built, removing low and reverse gears.

I started looking around for the rare bird that it was.

I found one locally, but the guy wanted $1200 for it.

(He had to be joking, of course.)

In the course of my phoning around to try to find the Muncie, I happened to think of Don Vesco, and I gave him a ring.

We chatted for quite awhile about many things, one being the Discovery television program, "Motorcycle Lightning," that had just aired.

I asked him if he'd seen it.

He said he had.

We discussed an inaccurate statement that had been made on camera by the 2002 Vibrac team's Crew Chief, concerning Don's involvement with the Vincent streamliner.

I told him that now I had my liner back, and I told him of all the changes I would be making in the creation of the new Black Lightning.

He agreed that I needed a stronger transmission for the new power plant, and said that he had the transmission that Bob George had built for his second streamliner.

I asked him what he wanted for it, and he replied , "It's yours my friend."

I thought he was being awfully quiet while I had been going on about how much I appreciated the gift of the transmission.

That's when he told me about his condition.

It was the last time I talked to my buddy, Don.

Build Diary

The following items, either bought with donated funds, or manufactured by team Vibrac, will be used on the new 2003 streamliner:

The manufactured parts are: rear wheel hub and wheel center disc, some bolts, rear axle, rollover switch, a portion of clutch release system, front axle, axle stops, front wheel disc, portions of the front steering mechanism, solenoid fuel shut off, solenoid skid valve system.

The bought items are: parachutes, tires, fire bottles, one two way air cylinder, four solenoid valves.

Donated items to be used are: shocks, both front and rear, rear chain cooling system, two wheel halves,

Approximate value of bought items is $4,600 (US)

The following items that pertain to the engines that team Vibrac either performed, modified, repaired or bought and installed are: valve guides.

Rear engine steel main support was manufactured and aligned.

Outboard main bearing outer races tightened by hard chroming cam side both engines, some welding on cases, hardened shoes on HYVO chain adjusters and hardened slap shoe on primary cover.

The cases were decked.

All of these items were of high quality, with excellent workmanship, and will be used on the 2003 attempt.

Skids

I've been working on the skids for the past couple of days, remachining the bits, and returning them back to my original adjustable design.

Fixed skids are not the way to go.

They must be adjustable.

There are three things that affect the streamliner's performance in handling, and the ability of the pilot to get it on it's wheels.

The number one thing that affects the liner's handling at high speeds is it's attitude when slicing through the air.

This attitude is accomplished by either changing the front suspension or the rear suspension ride height.

If the proper attitude has never been assertained, adjustable skids are a must.

The skids are midship both port and starboard.

They are lowered and retracted by a set of double acting air cylinders.

CO2 is prefered over air, as space is in limited supply and the size of bottle is small.

CO2 in liquid form at around 2000 lbs pressure, has much more expandable volume than air at 2000 lbs.

Hence, CO2 is used.

When the attitude is changed, as the skids are midship, the distance that the skids are off the ground is affected.

If the skids were hard on the ground, there would be no suspension action, which could couse all sorts of nasty things to happen.

The next thing is to figure out how much clearance to give the skids' shoes from the salt.

The pilot's task to get the liner off either the right or the left skid, is not an easy one.

The liner has a list.

The list is determined by the amount of distance the skid is from the salt--the more distance the more list.

The pilot has to physically flip the liner up on it's wheels, giving it an even keel.

this is done by turning first in the direction of it's list, causing the skid to leave the salt, then he must catch the liner when it's at an even keel, by moving the handlebars quickly in either direction to keep it there.

Not easy.

The pilot's feedback as to his preference for skid adjustment is invaluable to the tuner.

Factor number three has to do with the physics of gyro effects.

The liner has far more gyros going on than the average go back and forth to work scooter.

Blower drives, two engines--so when the liner is heading down the salt listing to one side and all of that stuff is spinning around in there and out there, the pilot has to physically change all those gyro axis' a few degrees and the Law of Physics, which states: "An object in motion tends to stay in motion", hence bang, bang, skid to skid.

You have to give the rider a bike he can ride, even the best can't keep it up on it's wheels if it isn't set up right.

|